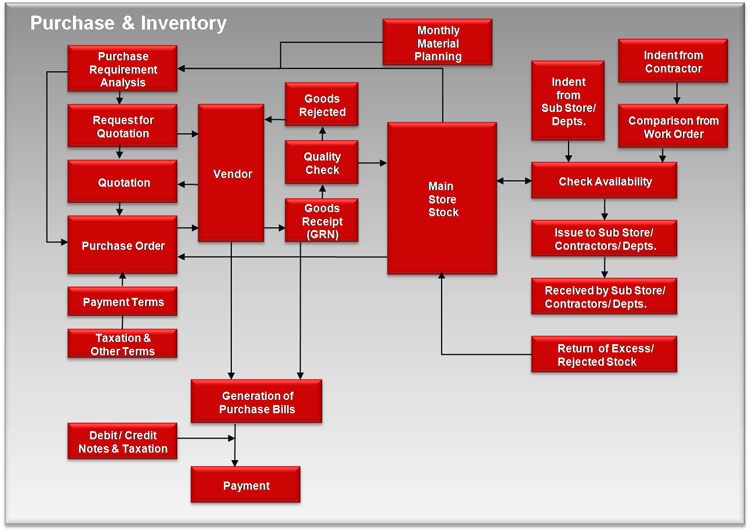

Purchase Requirement to Purchase Order till Purchase Invoice & Vendor Payments

This module deals with the inventory of all construction materials, consumables equipments & asset items at different project sites of the company along with their purchase and supplier details. The Store issues items/equipment to various users and details are recorded. Once the stock reaches below the reorder level, it generates a requisition for purchase. This also maintains records of purchases, stock, and supplier list, item/equipment/material master tables.

The Store module ensures that there is a round the clock availability of a sufficient quantity of materials in a mode that neither hinders efficient construction work, nor it becomes a financial burden on the company.

Salient Features

-

All Items are defined with their Group, Manufacturer, Batch, Expiry, Reorder Level, Opening Balance & Max Level. Rate defined for varying periods.

-

Purchase and Issue Unit of Measurement along with its conversion for each item. Option to Mark items as High Value.

-

Purchase Requirement Analysis from the Monthly work planning, taking into account pending indents, already ordered qty, Stock in Hand, Reorder level and Max level to compute accurate item requirement for the month.

-

Vendors details with Item Groups, Items & Rate Agreement other then Statutory and demographic details

-

Request for Quotation to Vendors, quotations received and comparison of all quotation to make decision for the Purchase order to the shortlisted vendor. Generate Purchase Order from Quotation/ Comparison automatically.

-

While generating Purchase order directly from Purchase Request, details of last ten Purchase Rate and the Stock qty displayed for all items.

-

Item Wise GST, HSN No, Discount & Free Qty in Purchase Order. Statutory informations like Taxation, Insurance, Freight, Delivery Terms & Payment Terms.

-

The items received via challan are entered and a Goods Receipt Note (GRN) is generated. GRN authenticate the items, manufacturer qty and other terms from Purchase Order.

-

Item stocks are updated on approval of GRN. In case there is some rejection , a GRN Rejection Transaction is entered.

-

All indents from Contractor and Departments are authenticated for Item Qty from contract/ project work template and items already issued against the respective phase and contract. No possibility of over Indenting of Items.

-

Items are issued to contractors and departments after validation of Indents, subject to availability of stock. Purchase request is generated for the pending Indents and also reflected in Purchase Request Analysis.

-

Items not consumed during the day or rejected as per the Daily Work Progress are returned to Store.

-

Purchase Invoice is generated either from the GRN’s quantity or directly if the invoice is received with the delivery of item. All Statutory terms are picked from the PO. Purchase return can be made after purchase invoice.

-

Vendor Payment. Payment of Purchase Invoice and credit notes for any period. Also payment for the Advance to be made to vendor and deduction of TDS accordingly.