Boost sales & build lasting customer relationships with our all-in-one CRM and Sales software

Success Result

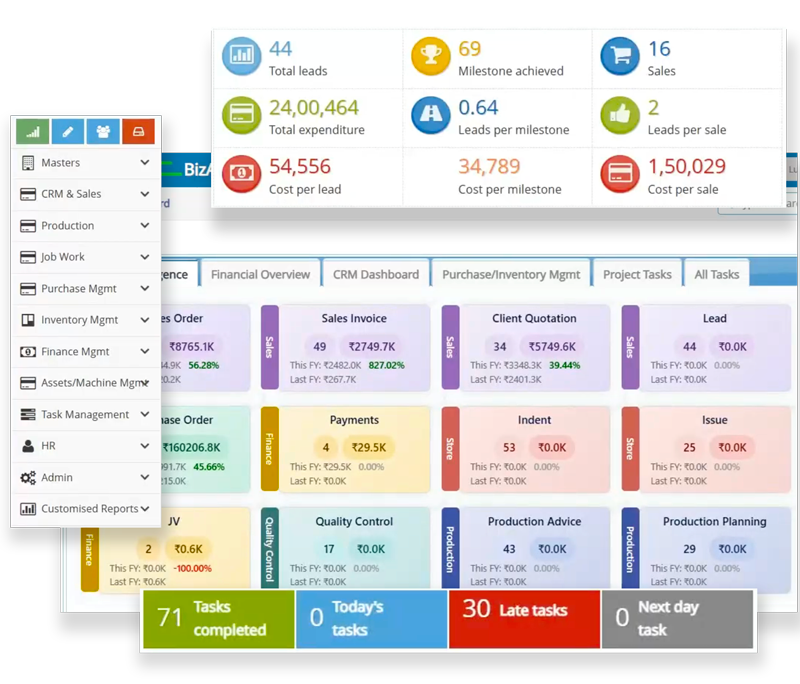

A SMART ERP SOLUTION FOR MANUFACTURING BY BIZACE

BIZ ACE is a specialized ERP system tailored for the Manufacturing industry, integrating core business processes with manufacturing operations. This unified platform streamlines various functions, including production planning, inventory, supply chain, and financial management.

Top Features of Biz Ace ERP Software

Sales Management

Lead and Opportunities, Detailed Follow-ups, Lead Source Analysis, 360-Degree Customer View, Win/Loss Analysis

Import Purchase & Export Sales

Multi-Currency Transactions, Tariff Management, Shipping and Logistics Management, Supplier & Client Performance Tracking

Production Planning & Control

Bill of Materials (BOM), Production Planning, Sales Order Integration, Make to Stock - Purchase Advice, Demand Forecasting

Real Time Production Scheduling

Production Calendars, Capacity Planning, Real-Time Scheduling, Job Card Creation

Multi level BOM

BOM Explosion, Process Routing, Machine, Output, Raw Material and Semi Finished Items

Purchase Management

MRP Integration for Purchase request, Vendor Management, Quotations Comparisons, Purchase Order, GRN, Invoice and Payments

Inventory Control

Real-Time Inventory Updates, Batch/Lot Tracking, Multi-Warehouse Support, Landed Cost Management, Inventory Audits

Advanced Quality Control

Standards Definition, Incoming Material Inspection, In-Process Inspection, Certification Management

Material requirement Planning MRP2

Sales Forecast Integration, Make to Order and Make to Stock, Net Requirements Calculation, Automated Purchase Request Generation

HR & Payroll

Employee Database, Leave Management, Attendance Tracking, Biometric Integration, Salary Calculation, KPI Management

Financial Management

Seamless Integration with Sales, Vendors & Job Workers Bills & Payments, General Ledger, Expense Management, Audit Trails & Reporting

Inward & Outward Job Works

Job Work Request, Work Contract Management, Job Work Status Tracking, Job Work Billing, Payment Reconciliation

Plant & Machinery Maintenance

Machinery & Vehicles Database, Machine Log Tracking and Maintenance, Maintenance & Breakdown Costing, Machine Audit Trail Analysis

E-invoice & E-way Bills

Integration with GST Portal, E-Way Bill & E-invoice Generation, E-Invoice Analytics, Audit Trail

Task Management

Detailed Tasks for Plants and Users, Sub Tasks and Multiple Comments, Documents Attachment, Analyse Task Progress, Graphical Task Dashboard, Task Scheduler

CRM

Lead and Opportunities, Detailed Follow-ups, Lead Source Analysis, 360-Degree Customer View, Win/Loss Analysis

Mobile Access

User-Friendly Mobile Interface, Role-Based Access, Real-Time Notifications, Multi-Level Approvals, Status Monitoring on the go

On AWS Cloud or On premise

Flexibility of Choosing what works best for you, be it SAAS/Cloud n AWS Servers or On-Premise Perpetual Model with data at your own Server

User Based Access Rights

User Creation and Management, Role-Based Access Control (RBAC), User Session Management, Audit Trail and Activity Log

Quick and easy Implementation

Dedicated Support team works round the clock to achieve 100% success in every implementation. Detailed Knowledge base for easy Learning.

Analytics & Reporting

Get All Reports for Better Decision Making and Insights

Reports & Analytic Dashboards

Process & Production Reports

Sales Report

Quality Control Reports

Comprative Reports

Dispatch Report

Compliance Reporting

Supplier & Vendor Reports

Brand Analysis Reports

Testimonials

All About Manufacturing ERP FAQs

Manufacturing ERP software is an ERP system specially designed for technical booster of businesses through its unified database system to simplify production operations. It automates business processes such as procurement, finance, workforce management, customer service management, and others.

It supports manufacturers in making effective plans and successful implementations of projects by systematizing crucial factors of manufacturing including material planning, production tracking, scheduling, and product life-cycle. Simplified production management helps accelerate the manufacturing process and improve finished product quality.

Enterprise Resource Planning (ERP) is a software with a variety of features that help small and medium-sized businesses achieve their ultimate goals. Let’s dig into the major features and functions:

- Finance & Accounts: ERP simplifies business operations and makes the financial processes transparent.

- Inventory Management: ERP applications permit real-time stock tracking to know the exact location of materials.

- Manufacturing Processes: ERP can handle all the manufacturing tasks virtually and eliminate errors.

- Quality Control: ERP software ensures that all the quality standards are adhering to all the environmental and quality standards producing finished products.

- Supply Chain Management: ERP software facilitates seamless communication between suppliers, manufacturers, customers, and vendors throughout the supply chain.

- Bill of Material (BOM): BOM includes a list of materials, components, and instructions essential for the production process. ERP system provides a platform to display all the information in a single framework.

- Order Management: ERP allows the supervisor to determine the number of goods manufactured and how much more resources are required.

- Procurement: Streamlining supplier selections and distribution for simplified product deliveries are major factors in ERP software.

- Human Resources: ERP offers flexibility in attendance, salary, and compliance to make the company’s workforce experience smooth working.

- Product Life Cycle: The ERP system tracks each stage of the product and helps to eliminate potential errors.

ERP system is an essential element for manufacturing businesses as it provides a unified platform to share data and information for proper planning, management, and delivering the functionalities to support manufacturing operations. The flexible support of the ERP system enhances and manages critical aspects of shop floor operations of manufacturing businesses.

- Increased Visibility throughout Production Process.

- Reduced Cost with proper allocation of resources.

- Automated processes for timely delivery.

- Improved supply chain management.

- Accessibility to compare metrics across the business premises.

There are many benefits of using ERP for the manufacturing industry. Here are some of the most important ones:

- Automates and Streamlines business processes with adaptability.

- Reporting & Easy forecasting.

- Decision-making Improvement.

- Greater employee efficiency with flexibility & mobility.

- Enhanced Productivity.

- Increased Data Security.

- Supply Chain Management.

- Quick Response to market conditions.

- Reduced Costs.

- Superb Customer Relationships.

Enterprise Resource Planning (ERP) systems are software suites that integrate all the essential aspects of an organization's business processes, such as accounting, manufacturing, sales, and human resources. ERP systems can be a valuable tool for manufacturing businesses, as they can help to improve efficiency, productivity, and profitability.

Here are the below advantages that can be achieved through ERP in the manufacturing industry:

- Improved visibility and control.

- Automated processes.

- Integrated data.

- Improved communication.

- Increased compliance.

- Reduced costs.

- Improved customer service.

- Increased agility.

The cost of ERP software for manufacturing businesses varies depending on a number of factors, including the size of the business, the complexity of the ERP system, and the level of customization required. However, in general, ERP software for manufacturing businesses can cost anywhere from a few thousand dollars to several hundred thousand dollars.

Here are some factors that can affect the cost of ERP software for manufacturing businesses:

- The size of the business.

- The complexity of the ERP system.

- The level of customization required.

- The cost of implementation.

- The cost of training.

Yes. Bizace ERP provides ERP Software for small, mid-sized, and large-scale Manufacturing and Production Industries. Bizace ERP is a cloud-based manufacturing ERP software that integrate business processes with ERP solutions for production, inventory, sales, customer, finance, etc.

ERP software for manufacturing industry that helps manufacturers and integrate core business process, production to payroll, inventory management, and handling your daily accounts and finances.

Some Key Benefits of ERP Software for Manufacturing Industry.

- Adopt the best manufacturing ERP to handle everyday finance, create custom reports, and track job costing.

- You can monitor the finished goods inventory.

- Scan, store, and receive products, and track a location record of each item within the warehouse.

- You can keep a record of checkpoints to make sure that products meet your customers’ specific needs.

The need for ERP systems in the manufacturing industry is becoming increasingly important as businesses strive to improve efficiency, productivity, and profitability.

Here are some of the key benefits of ERP for the manufacturing industry:

- Improved visibility and control

- Automated processes

- Better decision-making

- Increased compliance

Overall, ERP software can be a valuable tool for manufacturing companies of all sizes. By improving visibility and control, automating processes, and enabling better decision-making, ERP can help businesses to improve their efficiency, profitability, and compliance.

Here are some specific examples of how ERP can be used in the manufacturing industry:

- Production scheduling

- Inventory management

- Quality control

- Customer relationship management (CRM)

By implementing Absolute ERP software for Manufacturing, manufacturers can improve their efficiency, profitability, and compliance, and they can better meet the needs of their customers.

Production software is a category of enterprise resource planning (ERP) software that is used by manufacturing companies that manufacture their own products. It helps to automate the tasks involved in manufacturing, such as production planning, order processing, inventory management.

There are many different ERP software solutions available on the market, and the best one for your manufacturing business will depend on a number of factors, including the size and complexity of your business, your specific needs, and your budget.

Have a look at Best ERP Software for Manufacturing Industry in India:

- Bizace ERP.

- Genius ERP.

- Batch Master.

- Lighthouse ERP.

- Deacom ERP.

When choosing an ERP system for your manufacturing business, it is important to consider your specific needs and requirements. You should also consider the size of your business, your budget, and your IT infrastructure.

Here are some factors to consider when choosing an ERP system for manufacturing:

Industry-specific features: Some ERP systems offer industry-specific features that can be helpful for manufacturing businesses. For example, SAP S/4HANA has a number of features that are specifically designed for the automotive industry.

Scalability: Your ERP system should be able to scale as your business grows. If you are a small business, you may not need a system that can handle the needs of a large enterprise. However, if you plan on growing your business, you will need to choose an ERP system that can scale with you.

Cloud or on-premises: There are both cloud and on-premises ERP systems available. cloud systems are typically more affordable and easier to implement. However, on-premises systems offer more control and flexibility.

Cost: The cost of an ERP system will vary depending on the size of your business, the features you need, and the type of deployment you choose.

Vendor support: It is important to choose an ERP system that has good vendor support. You should be able to get help from the vendor if you have any problems with the system.

Once you have considered all of these factors, you can start to narrow down your choices and choose the best ERP system for your manufacturing business.

Here are some ERP implementation best practices for the manufacturing industry:

- Start with a clear understanding of your needs.

- Get buy-in from all stakeholders.

- Choose the right ERP system.

- Plan carefully.

- Communicate effectively.

- Test thoroughly.

- Support your users.

- Define Key Requirements and KPIs.

Here are some additional tips for ERP implementation in the manufacturing industry:

- Involve your manufacturing team in the selection and implementation process.

- Consider your future growth plans.

- Make sure the system is compatible with your existing systems.

- Get help from a qualified consultant.